How a Recoil Wire Thread Insert Works: Recoil wire thread inserts are rolled from high quality stainless steel wire with a diamond shaped cross section, wound to the shape of a spring thread. Once the insert is installed into a tapped hole, it provides a permanent and wear resistant thread in the parent material that is stronger than the original thread.

Recoil inserts are greater in diameter than the corresponding tapped hole and compress as they are installed. This allows maximum surface contact area with the tapped thread, safely and permanently anchoring the inserts into place. The insert’s compensatory action shares the load over the entire bolt and hole, increasing holding or pull out strength. With a Recoil insert in place, load and stress are more evenly distributed.

Recoil inserts come in a huge range of insert sizes from 2mm diameter up to 100mm and in virtually all thread forms including METRIC, UNC, UNF, BSC, BA, BSP, BSW and National Pipe Taper (NPT).

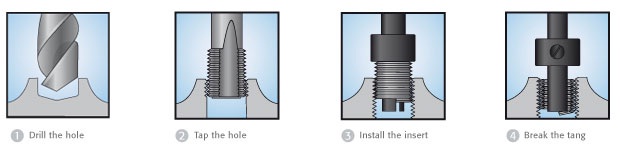

Installation takes only four easy steps:

- Drill the hole from it’s original size to the larger size required for the RECOIL insert.

- Tap the hole with the supplied tap to suit the RECOIL insert.

- Install the RECOIL insert with the supplied wrench.

- Break the tang off of the RECOIL insert with the supplied punch (or a pin punch).